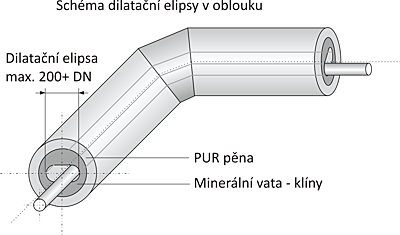

Bends with dilatation

For steam pipes, we use so-called elliptical bends, which are made so that that the service pipe has a space to dilate within the metal liner. The size of the dilatation joint depends on the layout scheme. The service pipe thus has space to dilate, and therefore does not compress the insulation layers (wool, PUR). This design reduces the number of axial compensators required to ensure that the system functions and thus extends the service life of the system.

So-called guidance pieces are added to these elbows, which come in standard lengths according to the table. These are straight pipes in which the ellipse is gradually reduced by a funnel to a normal dilatation joint on the pipe. Of course, elliptical pipes have larger casings (HDPE, Spiro) than straight pipes, so that the insulation layers of the required thicknesses can fit into the casing in addition to the ellipse. The diameter of the casing of the ellipse elbows is determined by the required size of the ellipse and the thickness of individual insulation layers.

Standard dimensions of elbows in ellipse:

| DN | L1 + L2 |

| 20 | 1000 + 1000 |

| 25 | 1000 + 1000 |

| 32 | 1000 + 1000 |

| 40 | 1000 + 1000 |

| 50 | 1000 + 1000 |

| 65 | 1000 + 1000 |

| 80 | 1000 + 1000 |

| 100 | 1000 + 1000 |

| 125 | 1500 + 1500 |

| 150 | 1500 + 1500 |

| 200 | 1500 + 1500 |

| 250 | 2000 + 2000 |

| 300 | 2000 + 2000 |

| 350 | 2000 + 2000 |

| 400 | 2000 + 2000 |

| 450 | 2000 + 2000 |

| 500 | 2000 + 2000 |

| 600 | 2000 + 2000 |

Elbow - standard

Standard lengths:

| Up to DN 100 | L = 1000 x 1000 | |

| DN 125 - DN 200 | L = 1500 x 1500 | |

| DN 250 - DN 600 | L = 2000 x 2000 |

Atypical elbow options according to the project documentation.

The steam system makes use of an elbow with a dilatation ellipse, where the service pipe moves inside the dilatation ellipse, and all insulation layers, including the HDPE casing, are rigidly connected and do not move. This dilatation is protected by a utility model.

Dimensions of the ellipse are determined in accordance with the dilatation calculation of the pipe and are entered into the layout scheme. The advantage of these elliptical elbows is that they replace axial bellows compensators and use natural compensation. So-called elliptical strains are manufactured for these elbows, and they are installed on site in front of and behind the elbow according to the layout scheme.